Do you find yourself frequently frustrated by premature tool deterioration or failure during turning operations? Understanding the four basic types of machining loads and how each affects your cutting tools can help you achieve slow, predictable tool deterioration as well as increase productivity and profitability.

The four load types are: mechanical, thermal, chemical, and tribological, and each one contributes to the wear and failure of your cutting tool. You’ll find these loads do not act independently, but rather interact and influence the sum of their effects on tool deterioration.

- Mechanical loads in turning are steady; however, any interrupted cuts during the process produces impact loads that can chip or break the tool.

- Thermal loads occur when workpiece deformation generates heat up to 1,650 degrees Fahrenheit, causing tool deformation and blunting.

- Chemical loads occur when heat and pressure combine between the cutting and workpiece materials, producing tool wear in the form of diffusion or cratering.

- Tribological loads happen when there is friction between the tool and chip, creating abrasion and erosion-type wear.

Strategy 1:

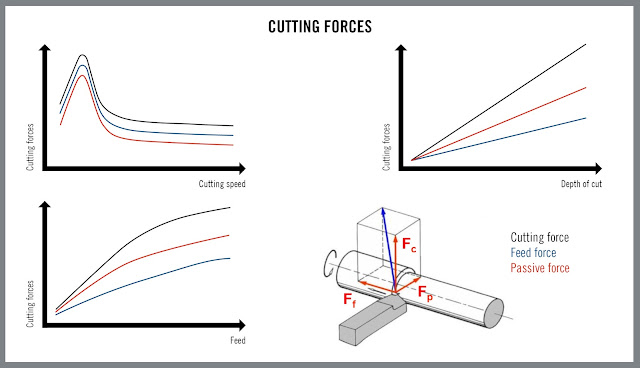

Manipulating your cutting parameters can influence the level of load impact on your tool. Keep in mind, however, depth of cut, feed and speed all have differing effects on machining loads, so you should consider the following:

- Doubling the depth of cut doubles the cutting force but also doubles the length of the cutting edge in cut. This results in the load remaining the same per unit of cutting edge length.

- Increasing feed rate increases cutting forces, but to a lesser, non-linear degree. Because the greater feed increases chip thickness, not the length of the tool in the cut, loads are seriously increased on the cutting edge.

- When increasing cutting speed, forces generally remain the same, but power requirements rise.

- Cutting forces rise at lower cutting speeds and decrease at higher cutting speeds. Watch closely for a built-up edge, which may indicate inappropriate cutting speed.

- Too high of cutting speeds can reduce the reliability of a process through uncontrolled chip formation, extreme tool wear and vibration that can make a tool chip or fracture.

- Higher feeds and depths of cut combined with low or moderate cutting speeds offer the best potential for operational security and reliability. Higher cutting speeds, if depth of cut and feed are sufficiently low to limit cutting forces, can provide greater productivity.

Strategy 2:

The basic size and shape of a tool determines its strength and capabilities. Often times, tool geometries are engineered with a specific application or workpiece material in mind. So, it's critical to have the best tool for the job right from the start. Here are a few things to keep in mind when selecting tools:

- A large, strong insert enables use of highly productive feeds and depths of cut because cutting forces acting on a large insert will result in lighter loads than the same forces would create on a smaller insert.

- A round insert shape is the strongest, and a 90-degree corner of a square insert is stronger than a 35-degree corner of a diamond insert. However, a round insert cannot cut the same variety of part profiles as a 35-degree tool. There is a tradeoff of strength for flexibility of application.

- Generally, the best tool for cutting steel, where toughness is required, has a honed edge. The best tool for cutting stainless steel, which tends to be gummy, has a sharp edge.

- Very sharp cutting edges may not necessarily provide the best surface finish. The best results often are obtained after an edge has run for a period of time.

Tool deterioration during machining is inevitable, but as you can see there are ways to slow the process and better predict when a tool will fail. Metal cutting is definitely a complex process, so any time you have questions or require applications advice, please don’t hesitate to contact me or our technical support team.

Read the published Seco technical article “Mechanical Loads and Cutting Geometries in Turning Operations.”

About the Author

Chad manages Seco's turning and advanced materials product lines, including all CBN and PCD products. When he's not helping customers implement advanced metal cutting solutions, you can find him training for and running 5K, 10K and 1/2 marathon races and triathlons.

it looks helpful to understand situation which happens during the machining!

ReplyDelete